We can manufacture all specially designed cables racks , assemble and deliver them accurately to the

customers , after the all planning which were created with understanding all customers perspectives.

MORI DENKI gains lots of experience which give all customers secured business relationship.

We are confident of our smooth job operation by avoiding time consuming work and materials loss at site.

MORI DENKI’s Smooth job flow from 1st call from customers through shipping our products to them without any time consuming procedures.

MORI DENKI can deal with any detail issue, turn to be a turnkey contractor in the assembly cable rack business field.

MORI DENKI’s original design come from much of

know-how based on wealth of experience.

Job flow from the beginning to the end

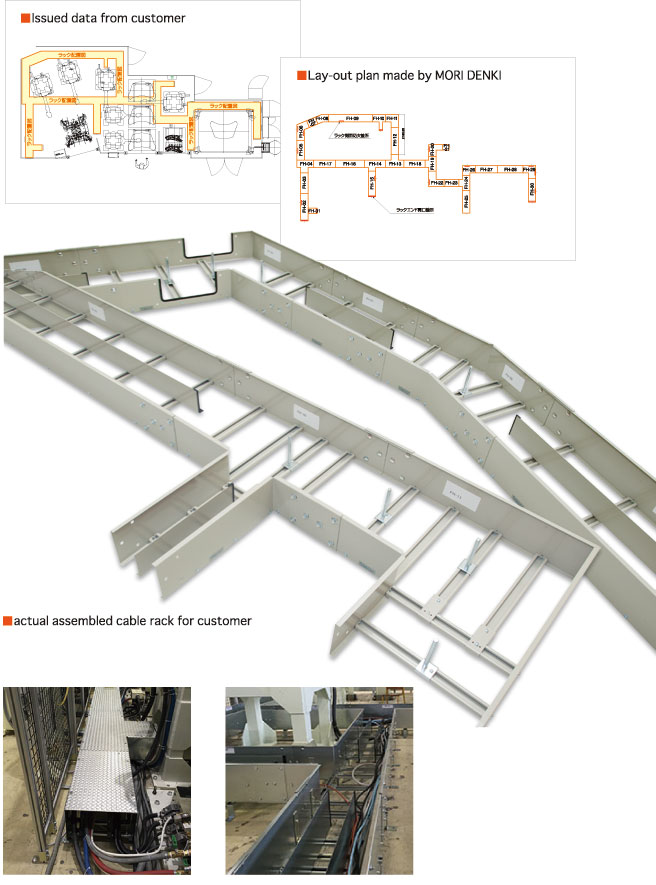

We can start our job with only receiving the data like machinery lay-out plan and rough drafts of ideas from the customers. Any data will do. Fax, Email, drawings and CAD data.

We create cable rack lay-out plan with combination idea of the best rack mix at fast, then, we come to a final plan in line with customer agreement. We try to communicate with them carefully on details.

Based on the lay-out plan, processing and assembly drawings are come up with by our expert staff. They can handle all sorts of request with ease.

Assembly each part components into a final assembled cable rack base on assembly drawing. Our quality products are made by our veterans for each customer.

Shipping the products with drawings to the designated place along customer request. They can install assembly cable racks on site with ease by only reference to the assembly drawing made by MORI DENKI "